The R44 Maintenance Manual is essential for ensuring the safety and longevity of the Robinson R44 helicopter․ It provides detailed procedures‚ safety guidelines‚ and compliance standards for proper aircraft upkeep․

General Information

The R44 Maintenance Manual outlines essential procedures‚ safety protocols‚ and compliance standards for the Robinson R44 helicopter‚ ensuring safe and efficient operation and maintenance practices․

2․1 Design Overview

The Robinson R44 helicopter features a robust and lightweight airframe‚ designed for durability and performance․ Its design incorporates a two-blade main rotor‚ a two-blade tail rotor‚ and a reliable Lycoming O-540 engine․ The aircraft is built with corrosion-resistant materials‚ ensuring longevity․ The R44’s design emphasizes ease of maintenance‚ with accessible components and straightforward systems․ Key features include a semi-rigid rotor system‚ a simple yet effective control system‚ and a fuel-efficient engine․ These elements combine to make the R44 a popular choice for both training and recreational use․ The design overview in the maintenance manual provides a clear understanding of the helicopter’s structure and systems‚ aiding technicians in performing effective maintenance and repairs․

2․2 Key Systems

The R44 helicopter is equipped with essential systems designed for reliable operation and safety․ Its hydraulic system ensures smooth control surface movement‚ while the electrical system powers critical avionics and lighting․ The fuel system‚ with two bladder-style tanks‚ provides efficient fuel management․ The engine oil system lubricates the Lycoming O-540 engine‚ maintaining optimal performance․ The cooling system effectively regulates engine temperature‚ preventing overheating․ Additionally‚ the R44 features a simple yet effective rotor system‚ with a semi-rigid design that minimizes complexity․ These key systems are integral to the helicopter’s functionality and are thoroughly detailed in the maintenance manual‚ allowing technicians to perform routine checks and repairs efficiently․ Understanding these systems is crucial for ensuring the aircraft remains airworthy and operates safely․ Regular maintenance of these systems is outlined in the manual to prevent potential issues and extend the helicopter’s service life․

Pre-Flight Inspections

Pre-flight inspections are critical for ensuring the R44 helicopter’s airworthiness and safety․ The maintenance manual outlines detailed procedures for inspecting all major components‚ including the rotor systems‚ control surfaces‚ and hydraulic components․ Pilots and technicians must verify proper functionality of flight controls‚ check for wear or damage on rotor blades‚ and ensure secure fastening of all hardware․ The manual also specifies checks for fluid levels‚ tire pressure‚ and avionics systems․ Additionally‚ the pre-flight inspection includes verifying the proper operation of the tail rotor gearbox‚ which requires draining and flushing every 50 hours of operation․ The R44 Cadet POH provides a printable pre-flight checklist to streamline this process․ Adhering to these guidelines minimizes risks and ensures compliance with safety standards․ Regular pre-flight inspections are essential for maintaining the helicopter’s performance and extending its operational lifespan․ Proper documentation of these checks is also emphasized in the manual․

Scheduled Maintenance

Scheduled maintenance for the R44 includes annual inspections and 100-hour checks‚ ensuring compliance with safety standards and preventing potential issues․

4․1 100-Hour Inspection

The 100-hour inspection is a critical component of the R44 maintenance schedule‚ ensuring the helicopter’s airworthiness and safety․ Conducted by certified technicians‚ this inspection involves a thorough examination of all major systems‚ including the engine‚ transmission‚ and rotor components․ Specific tasks include draining and flushing the tail rotor gearbox‚ inspecting belt tension and alignment‚ and checking for wear on critical parts․ The inspection must comply with the R44 Maintenance Manual and applicable aviation standards․ Proper documentation of findings and any required repairs is essential․ This process helps prevent potential failures and ensures the helicopter remains operational for safe flight․ Compliance with the 100-hour inspection is mandatory for maintaining certification and extending the lifespan of the aircraft․ Regular adherence to this schedule is vital for upholdingu0001ng safety and performance standards․

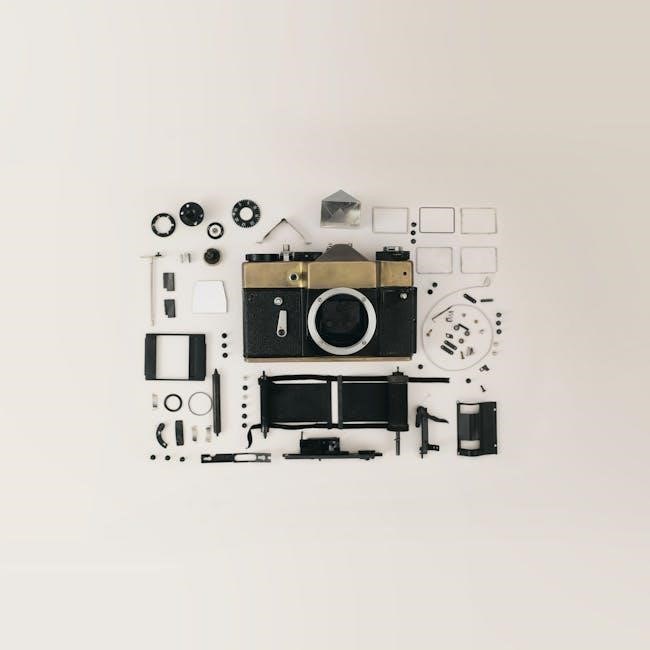

Tools and Equipment

Proper tools and equipment are essential for performing maintenance tasks on the R44 helicopter․ The maintenance manual specifies a comprehensive list of tools required‚ ranging from basic hand tools to specialized equipment․ These include wrenches‚ screwdrivers‚ torque wrenches‚ and hydraulic presses․ Additionally‚ specific tools like the tail rotor gearbox drain kit and belt tension gauges are necessary for precise tasks․ It is crucial to ensure all tools meet the manufacturer’s specifications to avoid damage or safety risks․ The manual also recommends maintaining a complete set of tools to streamline the maintenance process․ Adhering to the recommended tool list ensures compliance with safety standards and proper execution of repairs․ Always refer to the R44 Maintenance Manual for detailed tool requirements and usage guidelines to guarantee the integrity of the aircraft․

Airframe Maintenance

Airframe maintenance is a critical aspect of ensuring the structural integrity and safety of the R44 helicopter․ The R44 Maintenance Manual outlines detailed procedures for inspecting and servicing the airframe components․ Regular checks involve examining the fuselage‚ landing gear‚ and control surfaces for signs of wear‚ corrosion‚ or damage․ The manual specifies intervals for lubricating hinges and joints‚ ensuring smooth operation of movable parts․ Additionally‚ it provides guidelines for repairing or replacing damaged skin panels‚ rivets‚ and other structural elements․ Adherence to these procedures is essential to maintain the aircraft’s airworthiness and prevent potential failures․ Proper documentation of all maintenance activities is required to comply with safety regulations․ By following the airframe maintenance schedule‚ operators can ensure the R44 remains in optimal condition for safe and reliable flight operations․

Engine Maintenance

Engine maintenance is vital for the reliable operation of the R44 helicopter․ The R44 Maintenance Manual provides comprehensive instructions for servicing the Lycoming O-540 engine․ Regular tasks include oil changes‚ filter inspections‚ and spark plug replacements․ The manual specifies intervals for these procedures to ensure optimal engine performance and longevity․ Additionally‚ it outlines steps for inspecting fuel system components‚ such as hoses and injectors‚ to prevent contamination and ensure proper fuel flow․ Compression checks and magneto timing are also detailed to maintain engine efficiency․ Proper documentation of all maintenance activities is required to ensure compliance with safety standards․ By adhering to the engine maintenance schedule‚ operators can minimize the risk of engine failure and ensure the R44 remains airworthy․ Regular engine upkeep is crucial for safe and efficient flight operations․

Rotor Maintenance

Rotor maintenance is critical for the R44 helicopter’s performance and safety․ The R44 Maintenance Manual outlines detailed procedures for inspecting and servicing rotor components․ Regular lubrication of the rotor bearings and hinges is essential to prevent wear and ensure smooth operation․ The manual also specifies intervals for checking rotor blade balance and tracking to maintain optimal aerodynamic efficiency․ Visual inspections for cracks‚ delamination‚ or erosion on rotor blades and hub components are required to identify potential issues early․ Additionally‚ the manual provides guidelines for tightening rotor bolts and monitoring pitch link wear․ Proper documentation of all rotor maintenance activities is mandatory to ensure compliance with safety standards․ Adhering to these procedures helps extend the lifespan of rotor components and ensures reliable flight operations․ Regular rotor upkeep is vital for maintaining the R44’s airworthiness and operational integrity․

Transmission Maintenance

Transmission maintenance for the R44 helicopter is detailed in the maintenance manual to ensure optimal performance and prevent gear failure․ Regular inspection of the transmission fluid level and condition is crucial to maintain lubrication and cooling․ The manual specifies intervals for fluid changes and filter replacements to prevent contamination and wear․ Visual checks for leaks‚ cracks‚ or unusual wear on gear components are mandatory․ The transmission gearbox must be drained and flushed every 500 hours of operation to remove debris and old lubricant․ Proper torque specifications for bolts and fasteners are provided to ensure structural integrity․ Additionally‚ the manual outlines procedures for inspecting and replacing worn or damaged gear teeth․ Adhering to these guidelines helps prevent overheating and ensures smooth power transmission to the rotor system․ Regular transmission upkeep is essential for maintaining the R44’s operational reliability and safety standards․

Avionics and Electrical Systems

The R44 Maintenance Manual emphasizes the importance of regular inspections and maintenance for avionics and electrical systems to ensure reliable performance and safety․ Technicians must check all electrical connections‚ wiring harnesses‚ and circuit breakers for signs of wear or damage․ The manual specifies procedures for testing avionics components‚ such as navigation‚ communication‚ and instrumentation systems‚ to ensure compliance with safety standards․ Battery maintenance‚ including charge level checks and terminal inspections‚ is critical to prevent system failures․ Additionally‚ the manual outlines steps for updating software in digital avionics systems to keep them current and functioning optimally․ Proper grounding and shielding of electrical components are stressed to minimize interference․ Routine checks of lighting systems‚ including instrument panels and external lights‚ are also required to maintain visibility and safety during flight operations․

Inspection Checklists

The R44 Maintenance Manual provides comprehensive inspection checklists to ensure thorough evaluation of the aircraft’s systems and components․ These checklists are organized by frequency‚ including pre-flight‚ post-flight‚ and periodic inspections․ Detailed procedures guide technicians through visual inspections‚ functional tests‚ and measurements to identify potential issues early․ The checklists cover critical areas such as rotor systems‚ hydraulic components‚ avionics‚ and electrical systems․ Specific tasks include checking control linkages‚ examining rotor blades for damage‚ and verifying proper operation of flight instruments․ Compliance with these checklists is essential to meet safety standards and extend the aircraft’s service life․ The manual also includes forms for documenting findings‚ ensuring maintenance activities are recorded accurately․ By following these checklists‚ technicians can systematically address maintenance needs‚ preventing unexpected failures and ensuring the R44 remains airworthy․